A checklist for facility managers: key factors for drinking water quality

7-minute read

Maintaining drinking water quality in buildings requires a number of factors to be considered and monitored on a regular basis. We’ve put together a checklist of the most important components required to protect drinking water quality, together with some helpful explanations. Why not use Water Quality Month as an opportunity to assess whether drinking water hygiene in your building is properly maintained? After all: maintaining water quality is your responsibility.

1. Avoid being exposed to risks created by rarely used fittings

Check your building or buildings to see whether there are any rarely used tapping points. These might be in basements, for example, or other kinds of remote floors and rooms. If water is able to stagnate in the last section of the mains branch, bacteria can proliferate there before spreading back into the overall water mains from this section. Even in frequently used sanitary facilities, there may be fittings that are not used as often, such as when users only bother to use the wash basin taps that are the quickest to get to after entering the room. However, rarely used tapping points do not need to be dismantled as part of an expensive and time-consuming project. Instead, electronic fittings can help out here, which offer an option for executing automatic stagnation flushes. In this way, specified normal operation can be simulated by these electronic fittings, even if it can’t be achieved by regular use of the facility.

The WALIS E wash basin tap from SCHELL was developed especially for out-of-the-way tapping points, such as janitor’s rooms or garages. Thanks to its flexible installation options, whatever the structural circumstances, the tap is also ideal for use with utility sinks. The Charité Berlin project offers an excellent example of the importance of these sinks for drinking water hygiene. In this hospital, a utility sink is located at the end of the cold water mains branch, one floor above the theatres near to the air-conditioning system. This sink is used only occasionally for cleaning work, but because it is linked to the operating theatres, even the smallest deviation in usage or water temperatures could potentially be dangerous. At this sink, a WALIS E tap is installed, together with a temperature sensor, and centrally controlled by the SCHELL SWS Water Management System to provide reliable support for maintaining the water quality.

2. Avoid the pipe-in-pipe phenomenon and ensure flow speeds are adequate

Depending on the dimensions of the piping in the building, several fittings may need to be opened simultaneously to ensure that the flush operation maintains drinking water quality. If only a small stream of water flows through large pipe diameters, this water will pass only through the centre of the pipe. The flow speed needs to be high enough in order to create the necessary turbulent flow that flushes the entire pipe interior, right up to the pipe wall. To avoid Facility Management having to operate multiple fittings by hand for these kinds of flushes, this can instead be handled by the SCHELL SWS Water Management System. With SCHELL SWS, several fittings can be consolidated into groups by the SWS Server. Once set up, the grouped fittings flush at the same time according to specified parameters, ensuring that the piping is flushed through at sufficient speed – and without manual actuation.

3. Have your water temperatures checked

Keeping cold water cold and hot water hot in the piping system is extremely important. As cold water heats up and hot water cools down, this can allow the explosive spread of dangerous bacteria. Facility managers are responsible for ensuring that temperatures in the entire hot water system remain above 55 °C and temperatures in the cold water system do not exceed 25 °C. Chronic problems can occur, for example, if the hot water and cold water pipes are too close to one another in shafts, and hot water lines start to warm up cold water lines. Stagnation flushes can also offer a remedy here. The best results are achieved by combining together temperature sensors, electronic fittings and a water management system. If the SCHELL temperature sensors detect a deviation, for example, then the SWS Water Management System and the networked electronic SCHELL fittings can immediately trigger a flush operation automatically. This prevents a situation where bacterial concentrations in the water mains start to rise due to problematic water temperatures.

4. Carry out professional recommissioning after longer periods of absence

Periods of absence affecting building operations occur time and again as a result of long weekends, etc. Over the summer holidays, schools are often unused for weeks on end. The official definition of an interruption in use, however, is just 72 hours – and this will require a complete exchange of water. It is therefore important to plan ahead and ensure that recommissioning of the drinking water installation is carried out properly after periods of absence. Leak protection is another important topic for buildings when not in use. The SWS leak protection fitting can prevent water damage occurring outside building usage times while simultaneously supporting the maintenance of drinking water hygiene. This fitting shuts off the water supply either centrally or in parts of the system at times when the building is not in use, but opens and closes automatically for stagnation flushes.

5. Stay up-to-date even while out-and-about

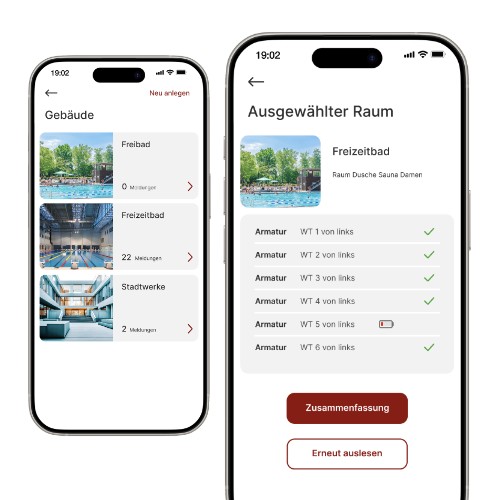

Obviously, you can’t be on site 24 hours a day. Nevertheless, you have to keep an eye on the drinking water quality in your building. Over the long term, the best way to do this is with the SCHELL SMART.SWS online service. Wherever you are in the world, SMART.SWS gives you instant, online access to your drinking water installation, estimated water consumption, service messages and much, much more – and for all of your buildings. Any necessary maintenance work, such as battery changes, can also be planned more easily and more efficiently. You can also use SMART.SWS to assign various roles to users. You might decide, for example, that your facility managers should only have access to a specific building, while your own account has a complete overview of all your properties.

6. Refurbish or renovate to maintain drinking water hygiene – without major effort

Switching to electronic fittings – perhaps combined with a water management system – offers plenty of potential for an approach to maintaining drinking water hygiene that is as simple and efficient as possible. This will also offers operational advantages – such as regulating water consumption, for example. This kind of renovation project does not need to involve major structural work, however. SWS-ready, electronic SCHELL fittings can be networked together as a wired and/or wireless system. This avoids the needs for additional power cabling or wall chasing work. Switching to electronic fittings and SCHELL SWS is therefore a straightforward move that gives you the best-possible support for protecting your drinking water hygiene.

For full details of how to go about maintaining drinking water quality, please also see the SCHELL SWS manual (page 30 ff.), which you can download here. Are you running a nursing home, a school or a local council building? The links given here provide you with specific information for these kinds of properties.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/1/b/csm_symstemloesungen_e2_thumb_6bca267f26.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/images/menu/menu_service_downloads_broschueren.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/7/csm_menu_unternehmen_ueber-schell_awards_f6cec25b1d.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/a/0/csm_menu_unternehmen_ueber-schell_wasser-sparen_41036d2dd9.jpg)