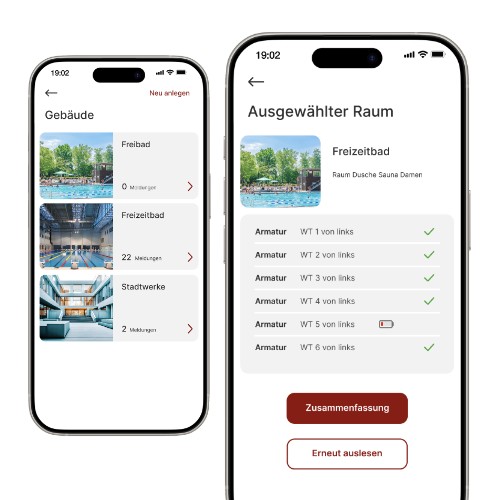

Developments in water piping layouts

Excessively long stagnation times for drinking water in the drinking water installation can lead to deposits and microbiological problems. To minimise these issues, the water piping layout is therefore extremely significant for maintaining drinking water hygiene. Since the 1990s, maintaining water quality in buildings has been an increasingly important point of focus for legislators, hygiene experts, fit-out planners, tradespeople and building operators. Manufacturers have also been considering product optimisations. In this post, we provide you with an overview of key developments in relation to water piping layouts and explain why T-piece installations are in most cases the most efficient and most hygienic choice for drinking water installations.

The basic precondition for maintaining drinking water quality within a drinking water installation is a regular exchange of water across all tapping points. This first became a binding regulation with the publication of VDI/DVGW Guideline 6023 in 2013. Even at the time, recent research findings showed that unused tapping points could become ‘dead pipes’, regardless of the actual water piping layout. To ensure the regular and complete exchange of water even during normal operations, the drinking water installation should be designed to be as ‘streamlined’ as possible: accordingly, its water volume should be as low as possible while keeping surfaces to a minimum. The same rule applies to tapping points: plan as many as are needed, but as few as possible. This ensures a high-volume exchange of water is achieved during normal operations. Drinking water installations that are designed to be ‘leaner’ also work to reduce the costs of materials and energy. In this way, drinking water hygiene and savings on energy or water are harmonised from the outset – also for stagnation flushes due to interruptions in use.

Venturi nozzles in ring-in-ring installations

For installations made from plastic, ring installations with the incorporation of all tapping points in a usage block are widespread. In addition, a simple distributor is connected to a distribution line that accepts both ends of the ring. From ISH 2007 onwards, there has been the option of incorporating tapping points using venturi nozzles and ring-in-ring installation. With a ring-in-ring installation, the tapping points in a usage line are also connected together using a ring line, but both ends of the ring are now connected to a venturi nozzle. This venturi nozzle is directly installed in a distribution line. Each venturi nozzle creates a head loss in the circuit – i.e. between both ends of the connected ring. This means that with each flow of water in the distribution line, a portion of the drinking water also flows through the respective connected ring. However, it should be noted that this principle works in one direction only: accordingly, if one of the tapping points is used in an upstream ring, then nothing whatsoever happens in the downstream rings. Extremely high quantities of flushing water are also required for a full exchange of water, because for a terminal flush, only 10% of the drinking water flows through the ring and 90% directly through the venturi nozzles. Accordingly, with each exchange of water, the stagnation water from the first ring partially ends up in each downstream ring, resulting in hygiene problems that can quickly spread to the entire building without an ‘extravagant’ exchange of water. Consequently, it is understandable that this kind of installation also does not exempt building operators from their duties (German Drinking Water Regulation (TrinkW) and codes of practice (DVGW W 551-4, VDI 6023 Part 1)) to use every tapping point. This is the only way to avoid unlawful ‘dead pipes’. Ring-in-ring installations are also questionable from an energy-saving perspective: in comparison with T-piece installations, these have a water volume that is around 25% larger and surface areas almost a third larger, which result in avoidable circulatory heat losses and situations where the cold water absorbs excessive amounts of summer heat, storing it in an oversized volume of water.

Alternative: serial mains

Serial mains were another option, where rarely used tapping points such as bath fittings or lines for irrigating gardens were also interconnected. For this installation variant, there was the additional recommendation of using terminal placement for frequently used tapping points like WCs. Later, these tapping points were then typically replaced by flushing stations, as electronic tapping fittings with flush functionality were largely unavailable at this time. However, as a result of the low nominal flow rate of typically only 4 or 10 l/min, flushing stations only offer basic support for an exchange of water, as they are simply unable to achieve relevant flow velocities in larger-dimensioned distribution lines or rings. This makes the actuation/triggering of multiple flushing stations or fittings necessary at the same time (VDI 6023 Part 1). High flow velocities of 1 m/s should be aimed for, so as to not only achieve a turbulent flow but also to create a flow velocity that has a ‘cleaning’ effect. Otherwise, deposits of sediment could form and an exchange of water would only take place in the centre of the piping. This situation is also referred to as the ‘pipe-in-pipe’ phenomenon.

T-piece installations: the best choice today for hygienic water piping layouts

The reduced volume of material used in smaller piping dimensions, insulation and pipe clamps makes them more ecological and less expensive than piping with large dimensions. The lower overall volume of water not only makes an exchange of water easier but has the benefit of reducing the surface area: this results in lower heat losses in circulatory lines while also protecting potable water cold (PWC) against avoidable heating. These arguments together with new findings from both theory and practice are (ideally) again leading to the implementation of drinking water installations primarily as T-piece installations. Only avoidable but rarely used tapping points are still designed as serial installations or ring-in-ring installations. Ultimately, the tried and tested T-piece installations offer fit-out planners, tradespeople and building operators a range of benefits:

- Clear flow paths in hydraulic terms

- Straightforward installation

- Low volume of water (−25%)

- Small surface area (−29%)

- Significant cost savings of 21%, for materials alone

Practical example: economic benefits of T-piece installations

An example from practice highlights the potentially huge savings achievable. In this case, the differences between the T-piece installation, serial installation and ring plus serial installation (ring-in-ring installation) variants were calculated for a real property, a high school with sports hall, in terms of the water volume in litres, inner surface area in square meters and the water carried by the individual supply lines.

The installation type ‘ring plus serial installation’ exhibited the highest volume of water and the highest inner surface area, while the T-piece installation achieved the lowest score, with a water volume for the individual line of 0.16 l per tapping point.

In the property investigated, the material costs for a T-piece installation were around 21% or EUR 53,000 lower than the material costs (excluding fitting costs) for a ring and serial installation (source: short study from Münster Technical College, Prof. Dr Franz-Peter Ing. Schmickler, M. Eng. Stefan Cloppenburg).

More information about the efficient and hygienic planning of drinking water installations can be found here.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/1/b/csm_symstemloesungen_e2_thumb_6bca267f26.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/images/menu/menu_service_downloads_broschueren.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/7/csm_menu_unternehmen_ueber-schell_awards_f6cec25b1d.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/a/0/csm_menu_unternehmen_ueber-schell_wasser-sparen_41036d2dd9.jpg)