Drinking water analysis: criteria for the sampling of drinking water

Drinking water is a perishable resource. Yet its deterioration cannot be detected without technical analysis. Accordingly, routine drinking water testing is prescribed by law for many types of buildings. While the residential sector follows a three-year cycle, properties used in healthcare or as hotels must be tested at least annually or even more frequently. To ensure robust results from the drinking water analysis, representative tapping points are to be defined and sampling must be carried out to professional standards.

Just like any other foodstuff, drinking water is a perishable good. If allowed to stagnate, bacteria such as Legionella can propagate to levels that are harmful to health. Depending on how the water is used, there are two separate ‘use-by dates’ for drinking water. If the drinking water is intended for direct consumption or use in preparing food, it should not have been present in the fitting and drinking water installation for more than four hours. When used for other purposes such as handwashing or showering, this period is extended to a maximum of 72 h without use. The four-hour period also applies when testing for material parameters, which can leach into drinking water comparatively quickly. The 72-hour period is primarily used for microbiological parameters, as bacteria require a certain amount of time to reach harmful levels. When commissioning water testing work, it is therefore important to specify the exact purpose of the testing, so that the laboratory can prepare the correct sampling vessels and take appropriate samples of water when on site. Water samples to test for material contamination must be taken (as S-0, S-1 and S-2) after water has rested in the pipes for four hours, while testing for Legionella is carried out during normal operation.

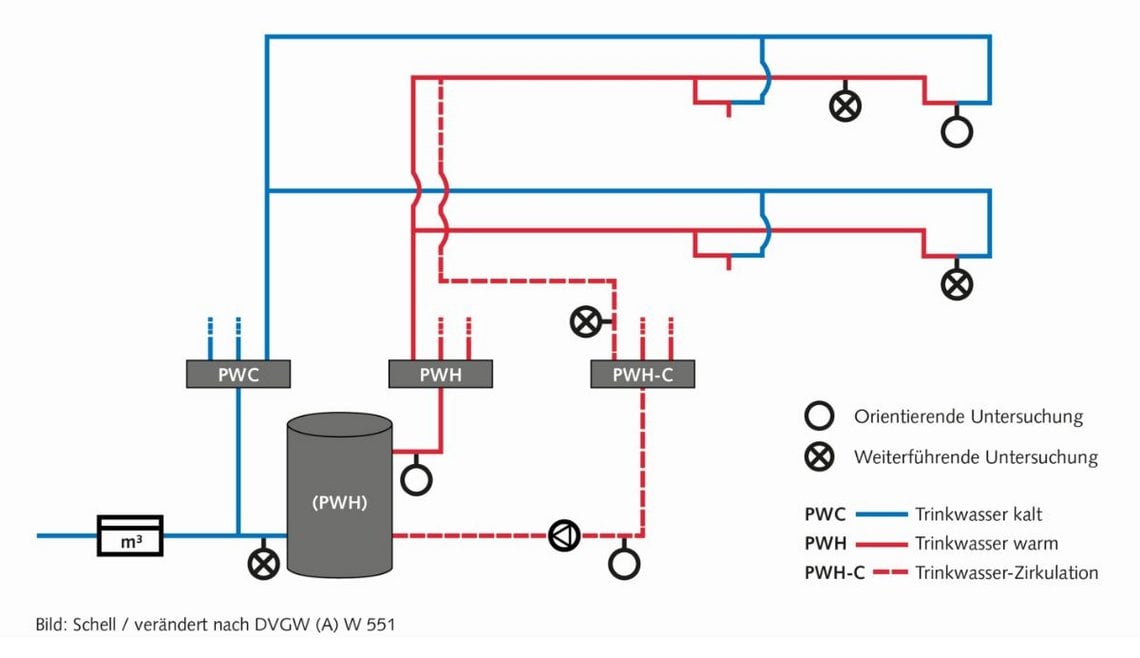

The same applies for the PWC line: within the overall system and at each tapping point, this must not exceed the familiar value of 25 °C after a maximum of 3 l have been drawn off, which is also measured in a volume of 250 ml (VDI 6023 Part 1). If there are indications that this 25 °C mark has been exceeded in PWC, then, for legal compliance, even this ‘cold water’ must undergo formal Legionella in drinking water testing (DVGW Worksheet W 551). A minimum number of sampling points must also be observed (see figure).

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/1/b/csm_symstemloesungen_e2_thumb_6bca267f26.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/images/menu/menu_service_downloads_broschueren.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/7/csm_menu_unternehmen_ueber-schell_awards_f6cec25b1d.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/a/0/csm_menu_unternehmen_ueber-schell_wasser-sparen_41036d2dd9.jpg)