Siphons, flush valves and more: taking care of hospital hotspots for drinking water hygiene – part 2

6-minute read

On premises used to care for people often suffering from severe health problems, maintaining drinking water hygiene could not be more important. In hospitals, maintaining drinking water hygiene has to overcome many challenges that need to be resolved in order to protect the health of all building users. In the second part of his post, SCHELL’s resident drinking water expert Dr Peter Arens presents more challenges and the solutions for these hotspots for drinking water hygiene. After comparing flush valves and cisterns in terms of their influence on hygiene for drinking water installations, he then goes on to offer some practical tips for their appropriate deployment. The challenges identified here are of course also relevant outside the hospital environment and helpful for maintaining water quality in many other kinds of buildings. In part 2, Arens turns the spotlight onto the following three challenges:

Challenge number 1: flushing siphons to reduce potential infections

Children’s wards present a particular kind of problem: apart from the usual wastes, unused liquid food mixtures and other potential sources of nutrition for microbes are often disposed of at the wash basin. “Personnel are often pressured for time, so the tap is run only until the basin itself is clean. At this point in time, however, food waste is often still present in siphon water, where it can later start to spoil,” Arens notes. To prevent this from happening, hospitals define risk areas where odour traps are either flushed out periodically with disinfectants or – a more effective method – the water in the siphon is electronically heated. But, as Arens explains, there’s another effective tool for supporting these disinfection strategies: fittings that are equipped with a configurable follow-up time and therefore let the water run on, even when users have already left the wash basin area. These taps flush the siphon clean of any remaining wastes. This useful setting is offered by many of SCHELL’s electronic wash basin taps, such as the VITUS series, which also includes a range of contactless models. “In some circumstances, taps like this can partially or wholly replace any additional disinfection strategies. “A defined ‘follow-up time’ of 30 seconds, for example (2.5 l), effectively replaces the siphon water volume multiple times and essentially makes it completely free of soap and food wastes,” Arens explains.

Challenge number 2: which is better – flush valve or cistern? A hygienic comparison

To simplify installations, cisterns are used much more often than flush valves, even though there are often good reasons for utilising such valves, especially in terms of their hygienic properties – as Arens explains. “Cisterns tend to be more popular than flush valves in installations for two main reasons. First, they can be connected to any kind of pipework, even if it only has a 12 mm diameter. Second, cisterns were often much quieter than flush valves in the past – although things have long since changed here. Flush valves like those from SCHELL now meet the highest requirements as set by noise class I (fig. 4). However, they still have the disadvantage of requiring at least a ¾" connecting pipe. Since the water volume in a stub line needs to be as low as possible, this often makes it impossible to connect flush valves at the periphery of a drinking water installation. If lines are at least ¾" in diameter, however, flush valves offer several hygienic advantages compared with cisterns: they can achieve a much higher flushing speed in piping, which means they prevent deposits, and without consuming water at a higher rate than a cistern would. Inexpensive, contactless models are also available – also good for hand hygiene – featuring dual-flush technology and with stagnation flushes if WCs remain unused for longer periods of time.” A good example of such a setup would be to combine the SCHELL COMPACT II concealed WC flush valve with the EDITION E WC control.

Flush valves also offer another decisive hygienic advantage compared with cisterns: they do not store water. “Ask any plumber about the grime – mostly black and often several millimetres thick – on the insides of cisterns, which you simply don’t get with flush valves,” comments Arens. “In light of these hygienic advantages, flush valves are always the solution of choice if ¾" connecting pipes are available anyway. A good example of this can be found in a hospital in Berlin, where the planners, well aware of the volume flow and hygiene issues, deliberately connected flush valves to the risers in order to ensure high flushing speeds here and the regular exchange of water. For renovation projects, retaining flush valve systems is always important for hygienic reasons if the ¾" pipes are to be kept or are present anyway. The speed of flow would be too low in these pipes if a cistern were to be used. So this explains why there are still good reasons, even today, for using flush valves (ideally contactless valves) if a minimum pipe diameter of ¾" will be present in the installation anyway.”

Challenge number 3: Features common to both flushing systems – downpipes

The last challenge to be mentioned in this post can occur with either flushing system, as it affects the downpipes used for cisterns and flush valves. An example illustrates the problem: A toilet bowl with a flush rim had been demonstrably contaminated with pathogenic organisms by a patient and had been exchanged for a toilet bowl without a flush rim. Although the patient could no longer use this bowl and even the toilet brush, etc. had been replaced, the same pathogens were again found to be present a few weeks later. “The most likely explanation here is that the bacteria had wormed their way up the downpipe as if it had been a urinary catheter and, in favourable circumstances, could well have made it as far as the cistern,” Arens explains. “Situations like this should also be considered on a case-by-case basis, depending on the significance of the pathogen and the type of ward.”

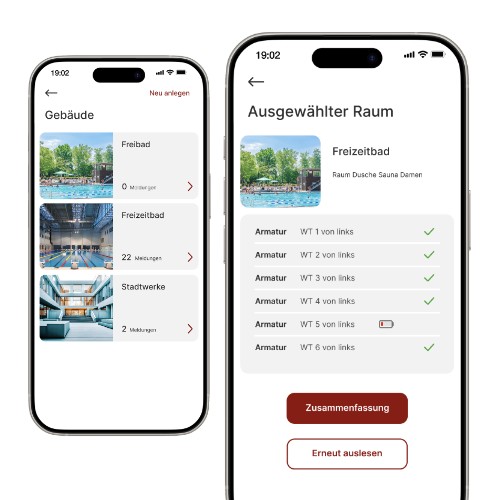

Help from SCHELL for maintaining drinking water hygiene

The last example in particular illustrates the complexity of drinking water hygiene as a topic for hospitals as well as the multifaceted nature of potential solutions. Much can be achieved, however, by products that have been designed from the outset to help maintain good drinking water hygiene. SCHELL’s guiding motto ‘Responsibility for Health’ is no empty boast, however, and the company offers a wide range of solutions that help to maintain water quality, such as electronic fittings and the Water Management System SWS. Make the most of our expertise – for drinking water installations in hospitals, other healthcare facilities and many other kinds of buildings.

For even more challenges and their solutions, read part 1 of this post on the topic of hospital hotspots for drinking water hygiene.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/1/b/csm_symstemloesungen_e2_thumb_6bca267f26.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/images/menu/menu_service_downloads_broschueren.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/7/csm_menu_unternehmen_ueber-schell_awards_f6cec25b1d.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/a/0/csm_menu_unternehmen_ueber-schell_wasser-sparen_41036d2dd9.jpg)