Sustainability comes naturally to us: SCHELL is not only a leading manufacturer of fittings and a leader in innovation when it comes to drinking water hygiene, but also a pioneer in terms of sustainability.

6-minute read

At SCHELL, sustainability has always been part of our company DNA. After all, Hubert Schell founded the company in Olpe in the heart of the Sauerland region – surrounded by fields, forests and waterways. That will definitely leave a mark ...

For SCHELL, economic success and a responsible approach to nature have been part of the company philosophy from the very beginning. An aspiration that the company still aims to meet even in times of globalisation. It achieves this, too, with intelligent fittings that save water, set hygiene standards while using energy efficiently to heat water. This goes hand in hand with long-lasting products that are manufactured with resource-conserving processes in mind. For instance, this includes the fact that the brass fittings, which are almost completely recyclable, can be returned to the raw materials cycle.

Resource-conserving fittings made in Germany

In 2008, the United Nations proclaimed it the “Year of Sanitation” – a testament to how important the subject of sanitary installations has long been worldwide. And no wonder: water consumption alone has sextupled since 1950. This is where spending on fittings that save water and energy offers a short return on investment. Expenditure on maintenance and servicing costs also has an important role to play. Intelligent fittings from SCHELL offer enormous potential for sustainable solutions – particularly in public, semi-public and commercial sanitary facilities. After all, this is where special conditions prevail. This includes differing user behaviour, greater hygiene requirements but also the risk of vandalism. For all of the above, SCHELL offers sustainable solutions that meet particular requirements. Extremely busy public places, such as airports, have to meet the highest standards, especially when it comes to hygiene in sanitary facilities; this is particularly pertinent in times of pandemics, making this topic more relevant than ever.

So it’s a good thing that SCHELL offers well-rounded solutions that perfectly unite design, efficiency and drinking water hygiene. Among other things, their surfaces have to be easy to clean and they have to have reliable mechanisms to protect against stagnant water. Those who choose SCHELL fittings never have to compromise on anything. Besides limiting the risk of infection, other issues play a key role, especially the mindful use of resources.

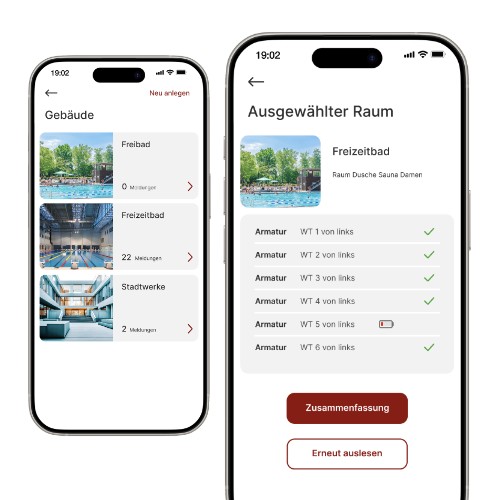

Airports, for example, are under great pressure to operate economically. This is why water-saving technology, as incorporated in SCHELL fittings for decades, is an enormous advantage for planners and operators. Not only that, but so is a vandal-proof, robust design, ensuring a long service life even with heavy use. SCHELL’s portfolio includes everything from wash basin, kitchen and shower fittings to angle valves, toilet and urinal flushing systems – plus matching installation modules, which are used, for example, in schools, nurseries, hotels and restaurants as well as in hospitals and care homes. SCHELL also has the right products for industrial and administrative buildings, railway stations and service areas as well as leisure facilities and sports centres.

Reducing water consumption – not convenience

Although 70% of Earth's surface is covered with water, only 3.5% of this water is fresh water – of that figure only half of it can be used. Drinking water is a valuable commodity as demand for fresh water is increasing in the face of climate change and a growing global population. In many countries around the planet, drinking water is a scarcity. SCHELL offers its products worldwide, not just here in Germany. It’s worth noting that in Germany’s households alone, around 64% of drinking water is consumed in sanitary facilities. For SCHELL, this is all the more reason to develop water-saving technologies that are most effective in areas where empirically speaking, awareness of the need to save water is at its lowest: in public, semi-public and commercial sanitary facilities.

From showers in sports facilities to toilets in motorway service stations and wash rooms in childcare facilities: SCHELL fittings are a smart choice and virtually take care of the saving themselves. For example, they only turn on when needed, i.e. at the push of a button or with no contact by a sensor; they limit the maximum flow volume and stop automatically at a set time. Compared to conventional fittings, water consumption when using the toilet can be reduced by 33% and when washing hands by up to 62%. This also saves energy when heating drinking water: the precise adjustment of the operating parameters, according to the needs of the building, such as sensor range, water flow time and follow-up time, ensures optimum user comfort without violating ecological requirements. At the same time, nothing has to be sacrificed, because the practical solutions are so ingenious that neither the function nor the comfort are compromised.

Durability and recyclability – tested and approved!

Fittings in public, semi-public and commercial sanitary facilities are tested to the limit on a daily basis: be it due to the sheer number of users, user carelessness or contact with a wide variety of cleaning agents. Sustainability can only be achieved in this scenario with uncompromising quality. For this reason, SCHELL insists on top-quality materials and on a design that will guarantee long service lives and the best protection in the event of any vandalism.

SCHELL’s product durability is not only a result of engineering excellence and superior robustness, but also stems from SCHELL’s typical approach to product design, which combines award-winning form with function. As experience has taught us: a more appealing design is less likely to be targeted by vandalism. The products and processes are tested continuously, and are certified to all of the relevant quality and safety standards. The production processes take place entirely in the SCHELL factories in Olpe in Sauerland, thus reducing logistics costs and unnecessary environmental impact. Furthermore, materials at SCHELL are used carefully to help conserve resources: an example of this is how all brass swarf and burr from the production processes are collected and returned to the brass manufacturer.

And should SCHELL fittings need to be replaced at some point by new ones, the old ones can be recycled.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/1/b/csm_symstemloesungen_e2_thumb_6bca267f26.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/images/menu/menu_service_downloads_broschueren.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/7/csm_menu_unternehmen_ueber-schell_awards_f6cec25b1d.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/a/0/csm_menu_unternehmen_ueber-schell_wasser-sparen_41036d2dd9.jpg)