Vacuumschmelze, Hanau

Redesign/renovation of sanitary facilities in the production area

Formed in Hanau in 1923, VACUUMSCHMELZE (VAC) is now a leading global specialist in the design, manufacture and application of magnetic materials. As a result of a growing workforce, full-scale renovations and extensions to the sanitary facilities in Hanau became necessary.

Project data

Conversion/renovation timeframe: May to August 2017

Developer: Vacuumschmelze GmbH & Co. KG

Number of employees (Hanau plant): 1,500 (approx.)

SCHELL products: Water management system SWS, XERIS E-T electronic wash basin tap, LINUS D-C-T concealed shower, LINUS DP-C-T shower panel, EDITION E urinal control, COMPACT II flush valve, MONTUS pre-wall modules

In contrast to the pragmatic approach taken with the old facilities, the renovation project aimed to follow the very latest standards in terms of architecture, functionality, drinking water hygiene and durability. A key priority here was the use of regular stagnation flushes as an important aspect of protecting the drinking water installation to maintain drinking water hygiene – and especially during company holidays.

The water exchanges also feature automated temperature control in the installation, with cold water and hot water both being regularly piped up to the tapping points. Another key concern here was to ensure an optimum balance between the factors of saving water and energy as well as user comfort, and measures taken to maintain and safeguard drinking water hygiene.

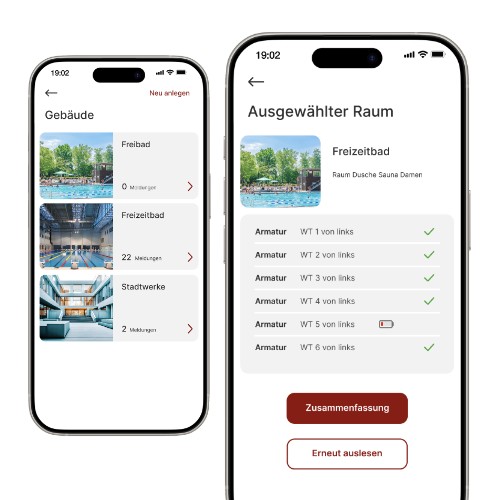

The sanitary facilities were gutted in full and renovated from scratch. The base element was a metal stud wall structure with the MONTUS pre-wall modules. All fittings were chosen for integration into a wired network using Schell’s SWS Water Management System. This ensures that VAC is provided with full data about usage, flushes and thermal disinfections. All uses of individual wash basins and shower cubicles are fully documented. This meant that the number of stagnation flushes could be adjusted to fittings that were used less often. As a result, drinking water hygiene is ensured at all times and at all tapping points, and its management not only conserves resources but is also very cost-effective.

All individual wash basins were fitted with the XERIS E-T wash basin tap, with integrated anti-scalding protection at 38 °C and automatic safety features to handle a failure of the cold water line. The fitting’s thermostat handle on the right offers precise and reliable adjustment of the desired temperature. In the shower cubicles, a large number of LINUS showers with pressure-sensitive CVD touch electronics were installed as concealed fittings and as shower panels. The easy-turn temperature controller and thermostat offer a high level of user comfort while showering. The water path to the showers also features anti-scalding protection, which shuts off the hot water supply if the cold water line fails.

Last but not least, contactless hygiene is also provided for the urinals. Electronic COMPACT II concealed urinal flush valves are installed here, together with the visually appealing EDITION E urinal control.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/1/b/csm_symstemloesungen_e2_thumb_6bca267f26.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/images/menu/menu_service_downloads_broschueren.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/7/csm_menu_unternehmen_ueber-schell_awards_f6cec25b1d.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/a/0/csm_menu_unternehmen_ueber-schell_wasser-sparen_41036d2dd9.jpg)