Würzburg University, Hubland Sports Centre

Hubland Sports Centre – all-out for fitness

In 2004, the Institute for Sports Science at the University of Würzburg acquired a new Sports Centre with a large outdoor sports facility and a modern indoor sports hall. Just a few years later, however, the sanitary facilities were already showing their age and unable to meet key hygienic requirements. SCHELL helped out here with tailor-made fittings technology.

With its new Sports Centre, the University was looking to create optimum conditions for educating up-and-coming coaches and ensuring all-round fitness for its students. The project was therefore appropriately ambitious, using a master plan from the city’s urban development team to add an individual axis to the original site, along which the various outdoor facilities were arranged. The gateway to this promenade is formed by the new sports hall and the stands for the large arena for competitive sports.

An unevenness in the terrain ensures that the varying spatial requirements for hall activities can be organised within a homogenous space. As a result, there is only a small offset between the hall roof and the roof of the utility rooms. Both areas still open at ground level onto roadways or the surrounding countryside. These high design standards are maintained in the shower facilities. Here, the showers are not arranged linearly as usual, but around rectangular ‘pillars’ in the centre of the room.

Invisible but indispensable

Openness and a deliberate arrangement of visual axes were important both for the design of the outdoor sports facilities and the architecture of the hall itself. In the shower facilities, however, one key risk was quite literally overseen. In these kinds of sports venues, regular flushing of the piping is important, since germs and bacteria like the dangerous Legionella can propagate rapidly during prolonged periods of non-use, resulting in serious risks to user health. With the fittings as originally installed, the corresponding hygiene standards were not achievable.

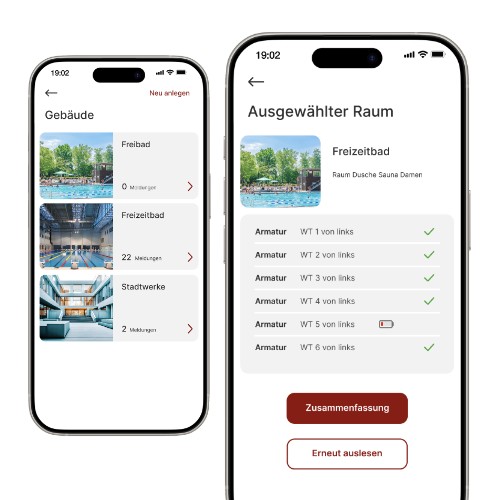

So the University’s Technical Operations team worked with SCHELL to find a solution. Electronic fittings technology from SCHELL was retrofitted behind the fittings panels on the 40 showers in the facilities. These were special, made-to-order units, since very little space was available in the pillars. As a result, stagnation flushes and thermal disinfections are now easy to carry out – and athletes can be confident not only of improving their fitness but also staying healthy while they do so.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/1/b/csm_symstemloesungen_e2_thumb_6bca267f26.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/images/menu/menu_service_downloads_broschueren.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/7/csm_menu_unternehmen_ueber-schell_awards_f6cec25b1d.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/a/0/csm_menu_unternehmen_ueber-schell_wasser-sparen_41036d2dd9.jpg)